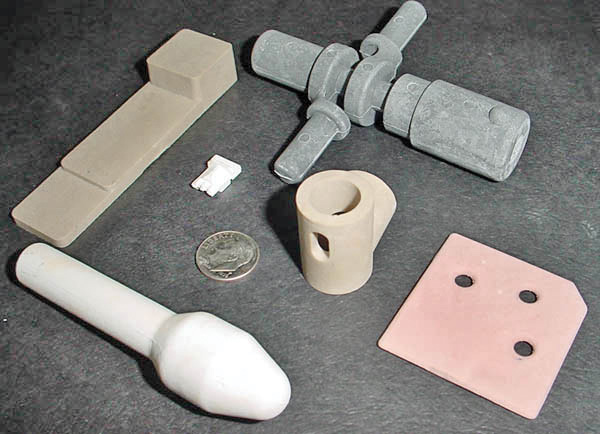

Ceramic Injection Molding

Your ceramic injection molding can be custom designed in house. Our engineering department employing CAD systems and technical expertise. Prototyping, testing and evaluating are all important aspects of producing the highest integrity parts. Our various ceramic injection molding formulations are well suited for many applications. These including electrical, refractory and leachable investment casting cores.

AKRON’s ceramic injection molding has the following advantages:

- Ideal for high-volume production of complex ultra-precision net shapes and sizes.

- offers the superior performance characteristics of ceramics along with the ability to attain extremely tight and uniform tolerances (+/-0.005″).

- Has the advantage of high-hardness, mechanical strength, wear-resistance and dimensional stability.

- Operates at high temperatures, with excellent electrical insulation and dielectric properties.

- Accommodates high volumes with multi-cavity tooling.

- Shorter lead-times and lower expense than convectional compression molding.

AKRON Porcelain & Plastics Company has the advanced technology to produce your next Ceramic Injection Molding (CIM) component(s), contact sales@akronporcelain.com today!

Industries Served

Electrical Distribution, Foundry, Major Appliance, Commercial Lighting, Water Filtration, Medical, Oil & Gas, Automotive