CERAMA-NUT® Wire Connectors (CSB-18 UL certified)

CERAMA-NUT® Wire Connectors from Akron Porcelain & Plastics are made of high-quality ceramics and have excellent electrical and heat resistant properties. CERAMA-NUT® Wire Connectors have a maximum working temperature of 1,000°F and are specified instead of plastic for applications above 200°F. Typical uses include any application involving elevated temperatures, such as appliances, high powered lighting fixtures, ceiling fans and heaters. Refer to cross-reference list below to compare plastic wire connectors and wire gage ranges for correct sizing. Akron Porcelain & Plastics stocks three sizes of CERAMA-NUT® Wire Connectors and can drop ship to your customer.

Please contact sales@akronprocelain.com to order any of these styles or to discuss your custom applications needs, Visa and MasterCard Accepted!

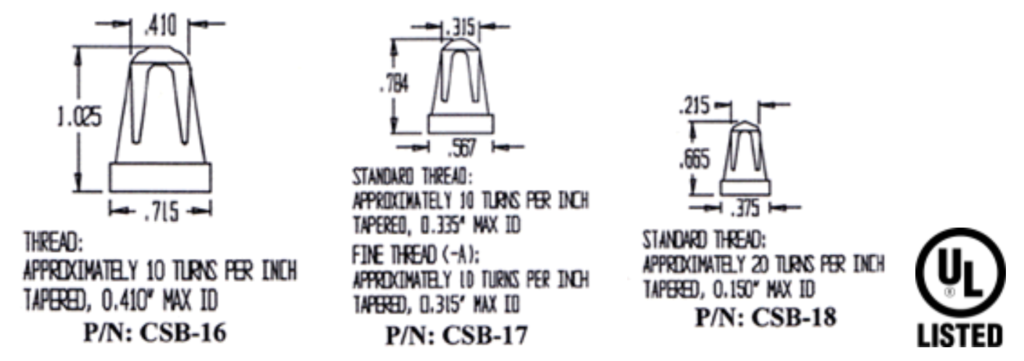

| AP&P Mold No. | CSB-16 | CSB-17 | CSB-18 |

| Size | Large | Medium | Small |

| Plastics-x Ref | Red | Yellow | Orange |

| Wire Gage | 18-8 | 22-10 | 22-14 |

| Style | Coarse Thread | Coarse Thread | Fine Thread |

| Pcs./Carton | 200 | 200 | 500 |

Industries Served

Electrical Distribution, Foundry, Major Appliance, Commercial Lighting, Water Filtration, Medical, Oil & Gas, Automotive

Wires used in equipment for storing and transporting medicines require special attention due to the critical nature of their applications. In pharmaceutical environments, maintaining precise temperature control and ensuring continuous power supply are essential to protect sensitive products. This places higher demands on the quality and durability of wire connectors used in refrigeration units, portable medical coolers, and storage facilities. CERAMA-NUT® Wire Connectors, with their superior heat resistance and electrical performance, are well-suited for these sensitive installations. Their ability to maintain integrity under elevated temperatures offers an added layer of reliability for equipment safeguarding valuable medications. Unlike standard plastic connectors, CERAMA-NUT® products provide long-term performance without degradation in high-demand settings. Using subpar connectors could lead to equipment failure, temperature fluctuations, and ultimately compromise patient safety. That’s why many pharmaceutical storage solutions are moving toward integrating ceramic connectors into their systems. Akron Porcelain & Plastics’ expertise ensures that customers receive the necessary reliability for mission-critical applications. Trusting the right components is fundamental when the integrity of medicine supplies is on the line.