How to Design a Thermoset Molding Plastic Custom Part

How to Design a Thermoset Molding Plastic Custom part. Input on the best molding method for the design concept & process should be early. Then the part shape can be optimized accordingly. This will ultimately reduce material and manufacturing costs. Akron Porcelain & Plastics can offer significant material and processing information to assist the product designer.

As with other plastic materials, good thermoset plastic part design requires consideration of a number of aspects. Tolerances, shrinkage, wall thickness, draft angles, radii, fillets, ribs, bosses, holes, threads, inserts, are all important. The following suggestions are fundamental practices to follow when designing a thermoset molded part.

Tolerances, Material Shrinkage, Wall Sections, Draft Angles, Radii and Fillets, Rib, Bosses, Holes, Threads, Parting Line Flash, Inserts, Quick Prototype Sample Parts, and Prototype Mold all information provided in Thermoset Molding Design Guide that can be found on Thermoset Molding Web Page.

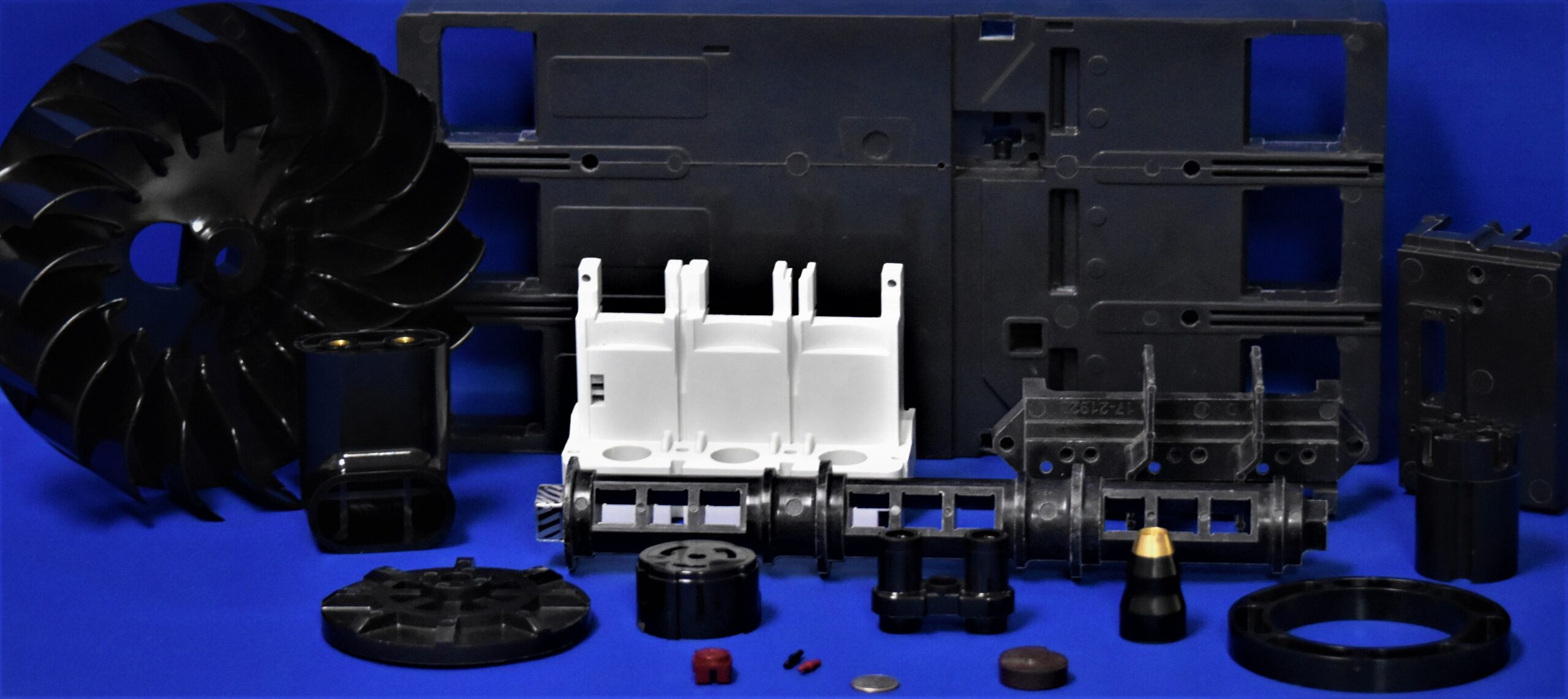

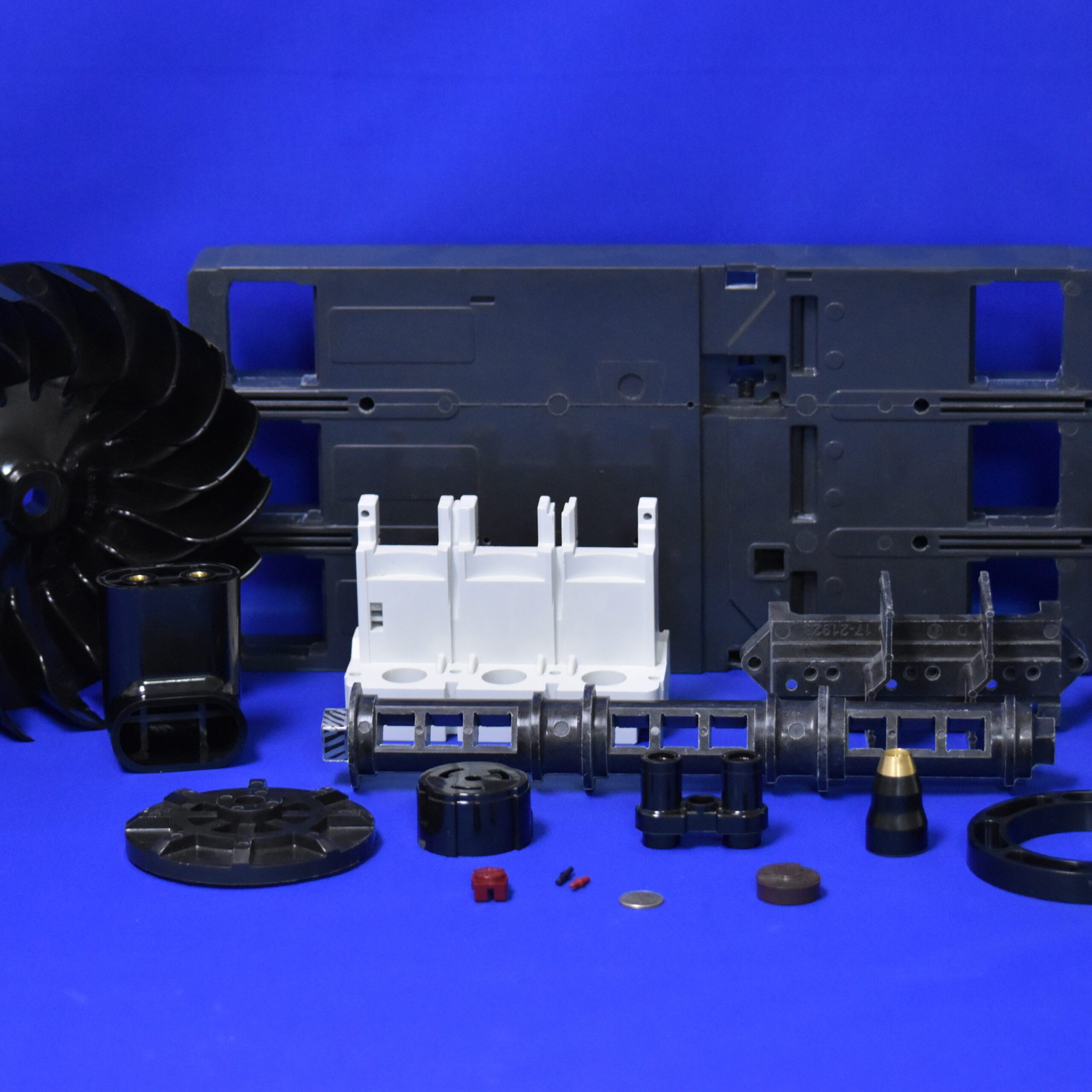

Thermoset Molding

Since 1957, AKRON Porcelain & Plastics Company’s engineers have designed hundreds of multi-cavity production tools. AP&P currently produce complex parts on a mass-production basis.

Thermoset materials from AKRON Porcelain & Plastics Company differ from Thermoplastic molding compounds. Due to a change in chemistry that occurs during the cure portion of the molding process. In short, the material “sets” up and “kicks” over into a different chemistry. That provides the desired molded part characteristics as stated above.

AKRON has the equipment, design expertise for both parts and tools. Plus, the plant capacity to handle any of your Thermoset molded needs. Thermoset Plastics continue to be very cost-effective on a cost-per-cubic-inch comparison to other plastic raw material selections.

Thermoset Plastic molding compounds were developed primarily to satisfy the following molded part criteria:

- High heat resistance while maintaining physical strength properties

- Chemical resistance

- Electrical insulation (arc & track resistance)

- Dimensional stability

Industries Served

Electrical Distribution, Automotive, Major Appliance, Commercial Lighting, Specialty Parts, Oil & Gas, Medical

Materials Technology

Phenolics – Injection/Compression, Glass Filled Phenolics Injection/Compression, Glass Filled Polyesters – Injection/Compression, Bulk and Sheet Molding Compounds – (BMC), Sheet Molding Compound – (SMC), Structural Composites, Ureas, and Alkyds.

Next Post

Next Post